In modern industrial production, environmental temperature and humidity are the hidden key factors that affect product quality,

production efficiency, and equipment lifespan. Whether it's precision electronic manufacturing, pharmaceutical production, food

processing, warehousing and logistics, overly humid air can lead to disastrous consequences: metal components rusting, products

getting damp and moldy, production lines coming to a standstill, and even electrical short circuits.

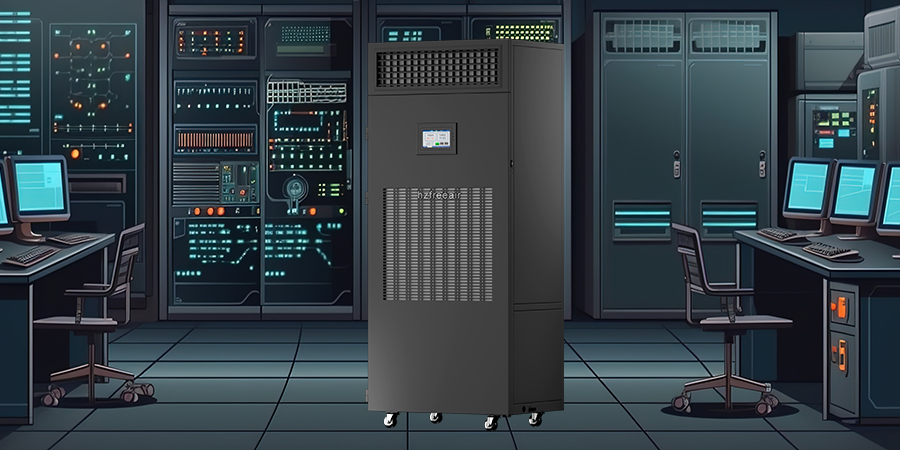

Traditional single dehumidifiers lose efficiency in cold environments. At this time, a "all-round player" steps onto the stage - an

industrial dehumidifier with heating function. It is not only the enemy of humidity but also the source of warmth, providing a

solid environmental guarantee for the non-stop industrial production throughout the year.

I. How to Work: The Precise Dance of Dehumidification and Heating

The core working principle of this all-in-one machine can be understood as the perfect combination of "energy transfer" and "

energy creation".

Core dehumidification principle (energy transfer):

The foundation remains the refrigeration cycle. After the compressor inside the device starts, it compresses the low-temperature

and low-pressure refrigerant into a high-temperature and high-pressure gas, which flows through the condenser (the outdoor unit)

and releases heat, then turns into medium-temperature and high-pressure liquid. Subsequently, these liquids pass through the

expansion valve for throttling, instantly turning into low-temperature and low-pressure mist-like liquid and entering the evaporator.

Key step of dehumidification: When humid air is sucked into the device by the fan and passes through the cold evaporator, the

water vapor in the air rapidly condenses upon cooling, just like the water droplets that condense on the outside of an ice-cold beverage bottle.

These water droplets drip and accumulate, and are then discharged, significantly reducing the absolute moisture content of the air.

Side effect at this point: Although the air after passing through the evaporator becomes dry, its temperature also significantly

decreases. If it is directly discharged, it will make the environment feel cold.

Intelligent heating function (energy creation and recovery):

This is precisely the essence of the "heating-enabled" machine. It achieves heating through two main methods:

Heat recovery heating (high efficiency and energy conservation): This is the most common and efficient method. A large amount

of heat generated during the refrigeration cycle (at the condenser) is usually wasted to the outside. The all-in-one machine, through

ingenious design, recovers this "waste heat" that was originally to be discharged and uses it to heat the dry and cold air that has just

been dehumidified and cooled. Thus, the final air blown out is dry and warm, achieving internal energy recycling and having an extremely

high energy efficiency ratio.

Auxiliary electric heating (precise and powerful): In scenarios with extremely low ambient temperatures or the need for rapid temperature

increase, the device will activate the built-in PTC ceramic auxiliary heating device. It is like a large "hair dryer", generating heat directly

through electrical energy and re-heating the air, ensuring that the outlet air temperature can meet the set requirements and providing

strong and stable hot air.

II. Advantages and Limitations: Viewing this "double-edged sword" rationally

Advantages:

All-weather, all-condition applicability: It breaks through the bottleneck of ordinary dehumidifiers where efficiency declines or

even freezes and stops operating in low-temperature and high-humidity environments. Whether in the cold winter in the south

or the cold warehouses in the north, it can perform dehumidification stably and efficiently.

Energy-saving and environmentally friendly: The heat recovery technology converts the waste heat generated during the cooling

process into a valuable resource, which is used for heating, reducing additional energy consumption and lowering operating costs.

One machine for two purposes, saving space and investment: No need to purchase separate dehumidifiers and heaters separately. One device can meet both needs, reducing equipment

procurement costs and floor space.

Improving working environment: In winter, it not only dehumidifies but also appropriately raises the workshop temperature,

avoiding workers feeling uncomfortable due to cold and dampness, and improving employee comfort and production efficiency.

Protecting equipment and products: Stable temperature and humidity environment can effectively prevent equipment from

rusting and control systems from getting damp and malfunctioning, and provide the best storage conditions for hygroscopic

materials (such as paper, wood, powder raw materials).

Limitations:

High initial investment cost: Due to its more complex technology and the inclusion of compressors and auxiliary heating systems,

the purchase cost is usually higher than that of single-function equipment.

Attention to operating energy consumption: Although the heat recovery is energy-saving, the power of the auxiliary heating module

is usually large. Once activated, it will significantly increase power consumption. It is necessary to set the temperature reasonably to

avoid unnecessary heating.

Not a professional heating device: Its core function is dehumidification, and heating is an auxiliary and derivative function.

For places that require extremely high environmental temperatures (such as steelmaking workshops), it cannot replace professional

industrial HVAC systems.

III. Examples of Application Scenarios: "All-Rounder" in Factories

Food Processing Factory:

Scene: Chocolate Candy Packaging Workshop. Chocolate is extremely sensitive to temperature and humidity. Low temperatures

can cause frosting (sugar frosting phenomenon) on the surface, while high humidity can lead to moisture absorption and mold growth.

Application: The integrated dehumidification and heating machine can precisely control the environment to be within the golden range of

18-20℃ and 45%-50%RH, ensuring that the chocolate does not melt or crack, and preventing moisture absorption, thus guaranteeing

the taste and shelf life.

Pharmaceutical and Biopharmaceutical Warehouse:

Scene: Warehouse for storing raw materials, Chinese medicinal materials, and capsules. These materials are highly susceptible to

moisture and deterioration, and there are also requirements for temperature stability.

Application: The integrated machine can maintain the warehouse at a low-temperature and dry environment (such as 5-15℃,

humidity < 40%RH) in winter, effectively preventing the aggregation and mold growth of drugs, and ensuring the efficacy and safety of the drugs.

Electronic Component Manufacturing Workshop:

Scene: SMT Soldering Workshop, Chip Packaging Workshop. Static electricity and humidity are the two major killers of electronic components.

In winter, dry air is prone to generating static electricity, but at the same time, it is necessary to prevent the risk of condensation water caused

by a sudden drop in temperature after night shutdown.

Application: The integrated machine can moderately dehumidify during the day and maintain an appropriate temperature, and run at a low

speed in the set mode at night to prevent the environment from being too cold or humid, avoiding oxidation and short circuits of the

precision circuit boards caused by condensation water.

Underground Equipment Depot and Parking Lot:

Scene: Underground water pump rooms, power distribution rooms, and parking lots of large factories. These places are generally dark

and damp, and in winter, they are extremely cold. The equipment is severely rusted.

Application: Installing the integrated machine can effectively remove the moisture brought by water evaporation, and slightly increase

the temperature, significantly reducing the rusting speed of metal equipment, ensuring the safe operation of power facilities, and

improving the ventilation environment.

Conclusion:

The industrial dehumidification and heating integrated machine, thanks to its intelligent collaborative operation, has become the

ideal choice for modern factory environmental control. It no longer simply and brutally addresses a single problem; instead, through

intelligent regulation, it creates a stable, reliable, and efficient "microclimate" for industrial production. Undoubtedly, it is an indispensable

"environmental guardian" in the era of intelligent manufacturing. When making a choice, enterprises should comprehensively evaluate

their humidity load, temperature requirements, and energy consumption budget, so that this powerful tool can maximize its value.