Industrial ultrasonic humidifiers play a pivotal role in modern industrial humidity control due to their high efficiency, energy

savings, and precise control capabilities. Their stable operation directly impacts production environment stability, product

quality, and equipment lifespan. To ensure long-term optimal performance and minimize unexpected downtime, a systematic,

scientific maintenance plan and efficient troubleshooting capability are essential. This guide aims to provide a comprehensive

maintenance and troubleshooting framework to help users enhance equipment management.

Part One: Scientific Maintenance Plan—Prevention is Better than Cure

Systematic preventive maintenance is the cornerstone of equipment reliability, centered on controlling water contamination

and performing regular upkeep.

1. Water Treatment: Ensuring Quality at the Source

Water quality is the primary factor affecting ultrasonic humidifier performance and lifespan. Minerals like calcium and magnesium

(scale) and impurities in water directly adhere to core components, causing efficiency loss or damage.

Pure Water Usage: Strongly recommend using pure water with resistivity ≥5μS/cm (e.g., reverse osmosis water, deionized water).

Pure water maximally prevents scale formation at the source, protects transducers, and reduces subsequent cleaning frequency—

representing the most cost-effective long-term investment.

Scale Remover Selection and Application: If ordinary water must be used due to constraints, or if scale has already formed on

the equipment, scale removers should be applied regularly.

Selection Principles: Choose acidic scale cleaners specifically designed for ultrasonic humidifiers. Avoid highly corrosive acids

(e.g., hydrochloric acid) or household vinegar. The former may damage metal components and transducer coatings, while the

latter offers low cleaning efficiency and may introduce organic impurities.

Application Guidelines: Strictly dilute according to product instructions and adhere to specified soaking times. After cleaning,

thoroughly rinse the water tank and water pathways with copious amounts of clean water to prevent residue corrosion.

2. Core Component Regular Cleaning and Maintenance Procedure

Follow the safety protocol: “Power Off, Drain Water, Operate, Reset.”

Transducer (Vibrator) Cleaning: This is the core maintenance task. After disconnecting power and draining the tank, carefully

remove the transducer guard or extract the transducer from the tank. Gently remove scale or deposits from the transducer

surface using a specialized descaling solution or a soft-bristle brush. Never scrape with hard objects to avoid damaging the

delicate ceramic coating. Ensure the transducer surface is dry and smooth before reinstalling.

Tank and Internal Water Circuit Cleaning: Periodically drain and clean the tank interior to remove algae, biofilms, and sediment.

For integrated water circuit systems, periodically circulate diluted descaling solution or specialized disinfectant, followed by

thorough flushing. Inspect and clean the water level float and sensor probes, ensuring their surfaces are free of contaminants

to maintain detection accuracy.

Filter Maintenance: If an inlet filter is installed, check and clean or replace the filter cartridge based on differential pressure

indicators or at regular intervals (recommended monthly) to ensure clean water supply and stable flow.

3. Routine Inspection Items

Daily: Verify normal operating sounds, stable mist output, and unobstructed water supply.

Weekly/Monthly: Check for smooth fan operation without abnormalities, inspect all electrical connections for tightness and

oxidation-free condition, clean equipment air inlets and outlets to prevent blockages.

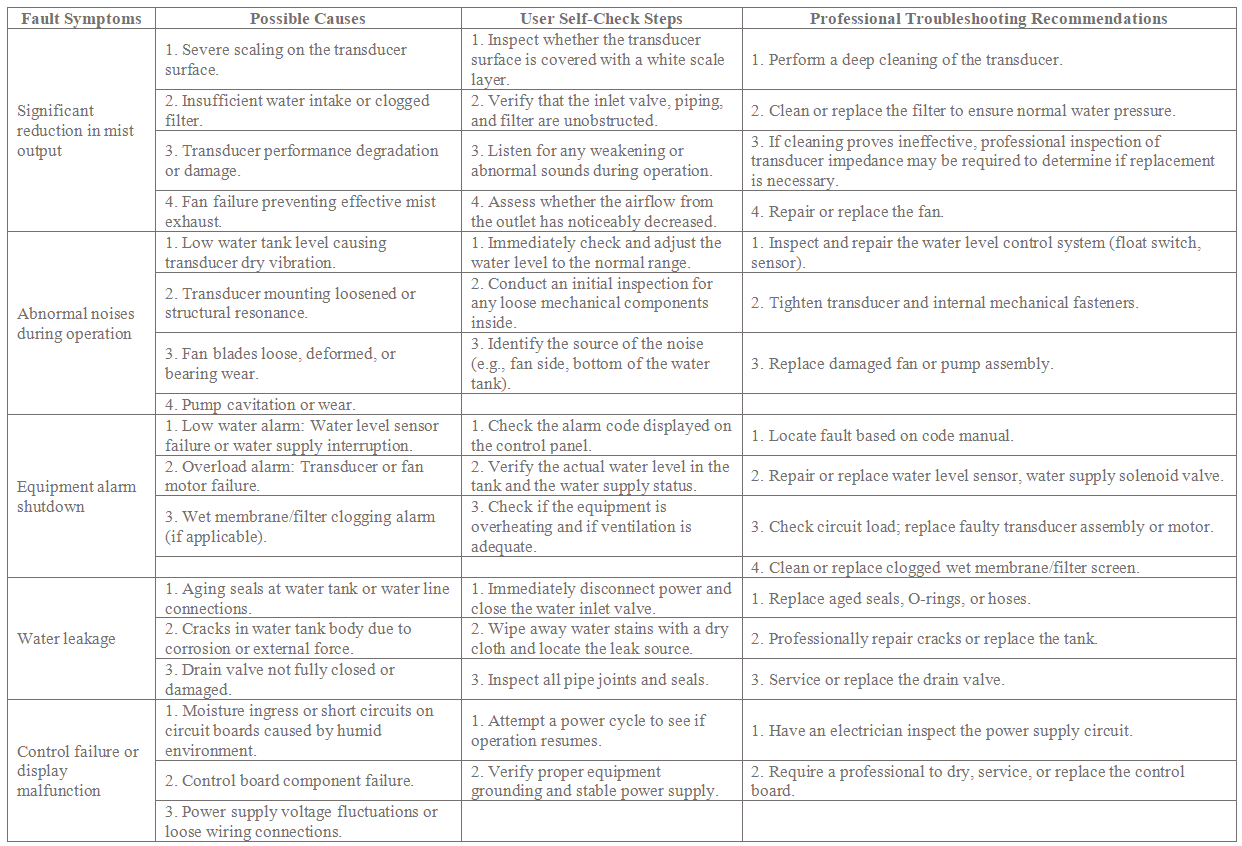

Part II: Troubleshooting Guide—Quick Diagnosis and Response

When equipment malfunctions, follow this procedure for preliminary diagnosis and resolution.

Important Safety and Operating Principles

Safety First: All maintenance and troubleshooting operations must be performed with the equipment completely powered off

and disconnected from the water supply. Working on energized equipment is strictly prohibited.

Follow Manuals: This guide provides general recommendations. Before performing any operations, always consult your equipment's

official user manual to understand the specific model's structure and requirements.

Documentation and Archiving: Establish and maintain a maintenance log for the equipment, recording each service, fault, and

resolution. This facilitates tracking equipment status and enables predictive maintenance.

Professional Boundaries: When users cannot resolve issues through self-inspection, or when complex circuit repairs or core

component replacements are involved, immediately contact the equipment supplier or professional maintenance personnel.

Avoid secondary damage or safety risks caused by improper operation.

Implementing scientific preventive maintenance and mastering systematic troubleshooting methods can significantly enhance the

operational reliability of industrial ultrasonic humidifiers, extend their service life, and ensure they consistently provide stable, efficient

humidity control for your production environment.